Stencil cutters are great tools for making stencils in any design you want. Store-bought stencils can be expensive and don’t give you the same satisfaction as creating a design yourself.

Having the power to make any stencil design under the sun almost seems too good to be true. But stencil cutters are actually quite ingenious and easy to use once you know how they work.

A stencil cutter generates a design by cutting through a stencil material. The cutting mechanism could be handheld or mechanical. Designs can be traced by hand or cut mechanically using a digital format.

This article goes over the different kinds of stencil cutters and some of their key components.

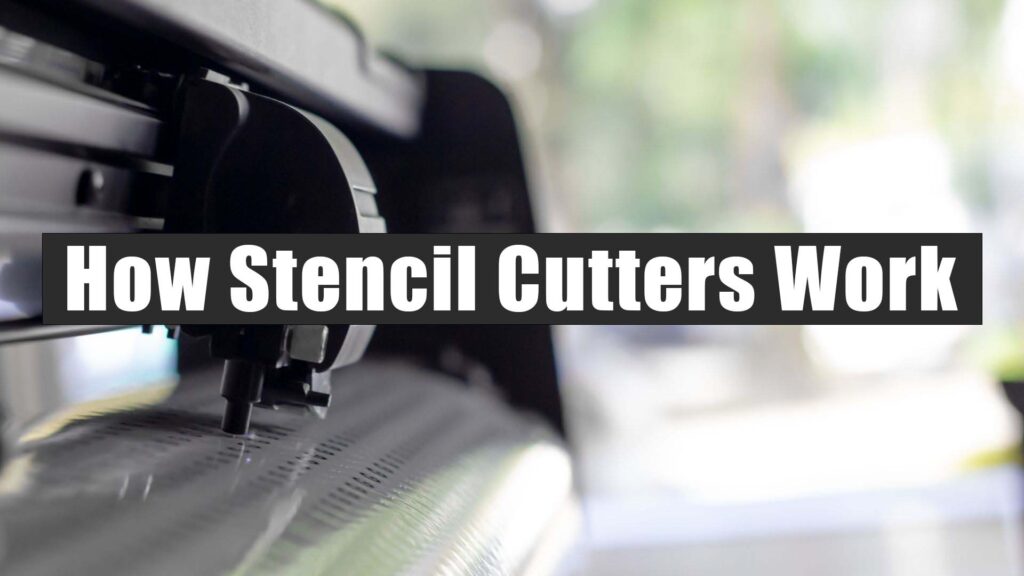

How a Stencil Cutting Machine Works

A stencil cutting machine cuts stencils by using an automated blade and roller system. The blade is guided across a cutting medium which is positioned by the roller system. In combination, these two mechanisms position the stencil material and make precise cuts.

The blade and rollers are driven by a drive motor, which follows a set pattern delivered by a digital signal.

NOTE: Many vinyl cutting machines can also act as stencil cutting machines. There are many similarities in the operational characteristics. Some machines marketed as stencil cutters are basically vinyl cutters with slight alterations. Conversely, many vinyl cutting machines also work perfectly well for cutting stencil materials.

For more info on cutting stencils with a vinyl cutter, check out the article below:

ARTICLE: How to Cut Stencils with a Vinyl Cutter

Drive Motors on Stencil Cutting Machines

Drive motors on stencil cutting machines move the position of the cutting blade and the position of the rollers.

There are two types of drive motors – mechanical steppers and digital servos.

Mechanical steppers use gears or magnets to determine the position of the blade head and rollers.

Digital servos use digital signals to control the blade and roller system.

The mechanical stepper style of the drive motor is slightly less precise than the digital servo because it uses incremental positioning. The digital servo uses more exact signals than gears in the stepper motor and is, therefore, able to cut smaller designs with more precision.

Here’s a good intro video to the difference between stepper motors and servo motors:

Stencil Cutter Machine Blades

The blade is the part of the machine that actually makes contact with the cutting surface and makes the cut. Its housed in the blade head which glides along the length of the cutting machine while the rollers simultaneously position the cutting medium.

Stencil cutter blades come in many shapes and sizes. Depending on what you want to cut, the angle, blade material, and size all come into consideration. Check out this article for more info on the different kinds of cutter blades:

ARTICLE: Vinyl Cutter Blades | The Ultimate Guide

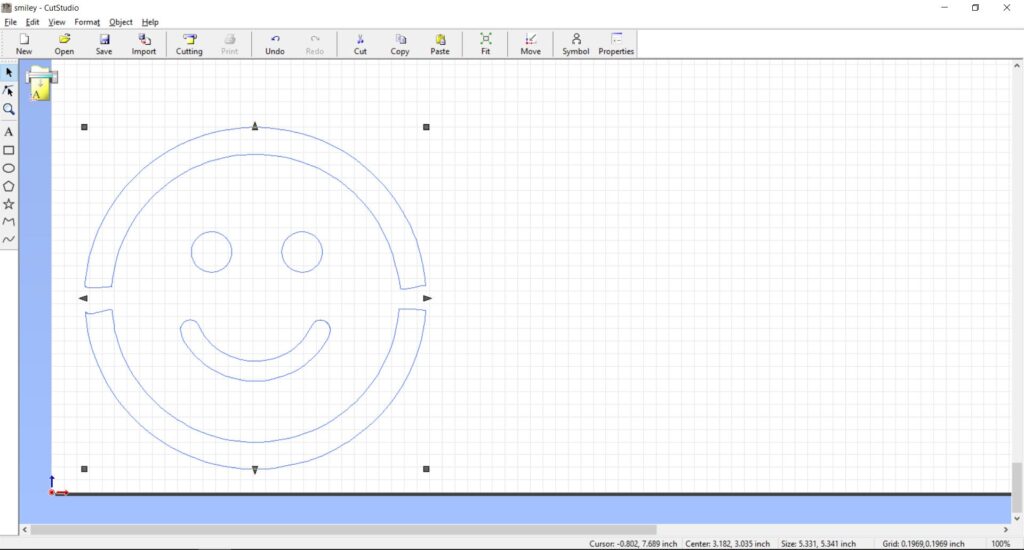

Stencil Cutting Software

Stencil cutting machines typically use a digital format to signal where the blade should move and make a cut.

Designs are loaded up on a computer program that turns the outline into a vector file. Vector files are a special kind of image file that is displayed using mathematical formulas. These formulas allow the file to be scaled infinitely smaller or larger.

Because of their scalability, vectors can be read by stencil cutting machines to make cuts.

Oftentimes, stencil cutting machines will come with software that makes vector files that can be read by the machine.

For example, the very popular Cricut Maker Stencil Cutter uses software called Design Space for making vector files that are compatible with the machine.

How a Handheld Stencil Cutter Works

Handheld stencil cutters are slightly less advanced than stencil cutting machines but still very effective.

The handheld options include exacto-knife style blades and heat tools with pointed ends.

Handheld Stencil Cutting with a Stencil Knife

Stencil cutting knives are pretty straightforward tools – by using a fine-tipped blade, you can make a cut on the stencil material in the outline of your design.

One of the most common ways to cut out freehand stencils is to trace along with a printed design or a freehand drawing. In this method, you take a transparent stencil material like a mylar sheet and place the design underneath.

The see-through material allows you to follow the lines and make cuts along the perimeter of the design.

Handheld Stencil Cutting with a Heat Tool

Stencil cutting with a heat tool involves burning/melting a design into stencil material (usually plastic).

Typically, the heat tool method uses the same tracing technique as the stencil knife. Some heat tools have fine tips or heated blades that are ideal for making precision cuts.

How to Make Stencil Cutting Designs

In order to design stencils, you can either freehand draw them or transfer them from a digital format.

Freehand drawing a design is straightforward – just use the stencil knife or the heat tool to “draw” a design. This method is simple and creative because you can just draw whatever you want.

Stencil cutting machines use digital vector files to program cuts. You can make a vector file by either choosing an image online or drawing a digital image using design software.

Online images are easy to find on Google Images by searching for outlines and silhouettes. Once you have an image that you want to turn into a stencil, you can just load it into your machine’s stencil cutting software where it can be turned into a vector file.

Digital design software such as Adobe Illustrator is great for making vector designs from scratch. Once you make a design on the software, it can be exported as a vector file and directly uploaded into the cutting machine’s software.

Whichever method you use, the machine will then take the design and cut out the stencil in a matter of minutes – making it very quick and easy.

Stenciling is a great part of many different art forms such as airbrushing, spray painting, sandblasting, and more.

Whatever kind of art you’re getting yourself into, I hope this article has given you the info you need to start stencil cutting like a pro.